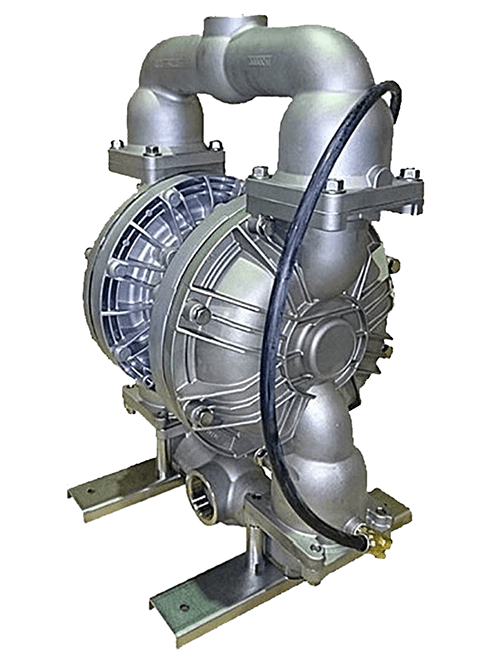

2:1 High Pressure AODD Pumps

Ratio 2:1 High Pressure Pumps are designed for applications where very high liquid discharge pressures are required to overcome system requirements. Pumps produce double the liquid discharge pressure utilizing standard air inlet pressure. Often used in filter press applications or when operating against very high back pressures or very long discharge lines. Can easily transfer highly viscous liquids or solid laden slurries.

Key Features of High Pressure Diaphragm Pump

- 100% Pneumatic Operation

- Doubles Liquid Discharge Pressure

- For Transfer of Slurries & Large Solids

- Can Run Deadheaded without Pump Damage

- No Need for Pressure Relief or System Bypass

- Highly Reliable Mechanical Spool Valve

- Compact & Robust Construction

- All Bolted Design

- Outside Accessible Air Motor

- 100% Non Lubricated Air Motor

- Available on All Metal Pumps 3/4” to 3”

- Designed for High Performance Operation & Long Life Expectancy

Advantages of Using High Pressure Diaphragm Pump in Filter Press Applications

IwakiAir’s high pressure diaphragm pumps offer various advantages when utilized in filter press applications:

High Pressure Capability: One of the principal benefits is their capacity to generate and sustain high pressure. This is critical in filter press applications, where the slurry must be forced into the press under high pressure to force the liquid through the filter media, successfully separating solids from liquids.

Utilization of Air for Operation: Filter presses utilize air to control hydraulic opening and shutting, as well as the air blowdown procedure. Because air is already utilized in these operations, a high pressure air operated diaphragm pump is the optimum choice for powering a filter press. Furthermore, this eliminates the requirement to supply energy to the filter press.

Heavy Duty Utilization: Filter press operations often involve a thick slurry or sludge containing a wide range of particles of variable sizes. The diaphragm pump is heavy-duty and specifically built to work with a variety of waste streams. It can handle very low and very high solids.

Flexibility of Use: Filter presses are used in a variety of applications. The diaphragm pump is suitable for a variety of applications, including wastewater treatment, mining, stone cutting, food grade filtration, and more.

Dry Running Capability: Our high pressure diaphragm pump are built to withstand dry running conditions without damage. This function is useful in filter press situations where intermittent operation or fluctuations in the slurry supply may occur, lowering the chance of pump failure.

Self-Priming: Our high pressure diaphragm pump are self-priming, meaning they can evacuate air from the suction line and create a vacuum to draw the slurry into the pump without the need for manual priming. This feature simplifies installation and operation, especially in situations where the pump is located above the level of the slurry source.

Filter Press Pumps – Making the Right Choice for Filter Press

Choosing the right high pressure diaphragm pump for a filter press is critical to achieving efficient operation and optimal filtration results. Here are some important aspects to making the appropriate decision:

Flow Rate Requirements: Determine the required flow rate for your filter press application. The pump should be capable of delivering the necessary volume of slurry to the press within the required timeframe to achieve efficient filtration.

Pressure Rating: Consider the pressure requirements of your filter press. Choose a filter press pump that can generate and maintain the required pressure to force the slurry through the filter medium effectively. High pressure diaphragm pumps are often preferred for filter press applications due to their ability to provide consistent high pressure.

Type of Slurry: Consider the characteristics of the slurry being processed, such as viscosity, abrasiveness, and solids content. Choose a filter press pump that is suitable for handling the specific properties of the slurry to prevent clogging, abrasion, or damage to the pump components. High pressure diaphragm pumps are often capable of handling abrasive or corrosive slurries commonly encountered in filter press applications.

Material Compatibility: Ensure that the pump materials are compatible with the slurry being processed to prevent corrosion or contamination. Consider factors such as chemical compatibility, abrasion resistance, and suitability for food-grade applications if applicable.

Self-Priming Capability: Opt for a pump with self-priming capability to simplify installation and operation, especially if the pump needs to draw the slurry from an elevated source or if intermittent operation is expected.

Maintenance Requirements: Evaluate the maintenance requirements of the pump, including ease of maintenance, availability of spare parts, and frequency of servicing. Choose a pump with low maintenance requirements to minimize downtime and maintenance costs.

Frequently Asked Questions About High Pressure Diaphragm Pump

What is the best Filter Press Pump?

The ideal filter press pump for industrial filtration applications is frequently decided by specific requirements such as flow rate, pressure, and material compatibility. However, Iwaki Air pumps are typically regarded as reliable, efficient, and versatile, making them a popular choice. Iwaki Air pumps, with their sturdy construction and air-operated diaphragm technology, provide efficient and reliable operation that requires low maintenance while maintaining safe filtration operations.

What are High Pressure Diaphragm Pumps, and how do they work in Filter Press applications?

High Pressure Diaphragm Pumps are specialty pumps that produce and maintain high pressure, making them excellent for moving fluids through a Filter Press system. In Filter Press Pumps applications, these pumps play a critical role in efficiently separating solids from liquids by driving the slurry through the filter media under high pressure.

What is the pressure on a filter press pump?

The pressure on a filter press pump varies based on various factors, including the pump’s individual design, filtration system features, and filtering process needs. Filter press pumps can generate pressures ranging from a few to several hundred pounds per square inch (psi). The pressure necessary for efficient filtration is determined by several parameters, including the viscosity of the fluid being filtered, the size and design of the filter press, and the desired filtering rate. Filter press pumps are typically intended to generate enough pressure to effectively force liquid through filter media, allowing solids to be separated from liquids.

Get Social