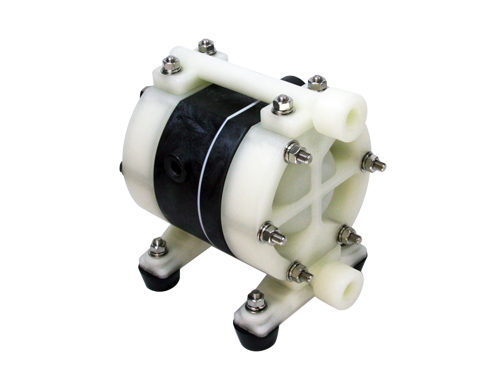

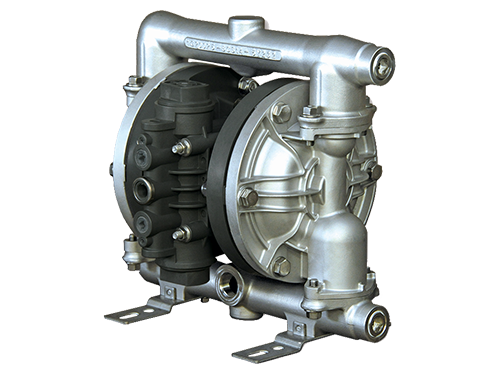

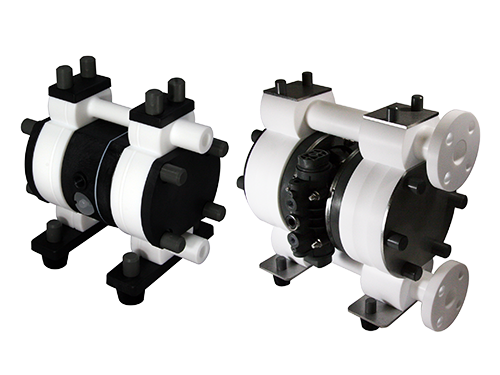

3/8″ TC-X100/101 Series

Maximum Flow Rate: 6.1 GPM (23 LPM)

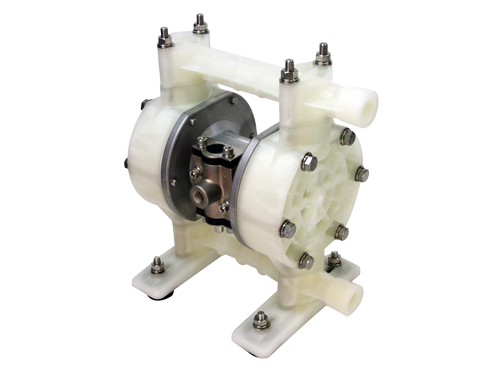

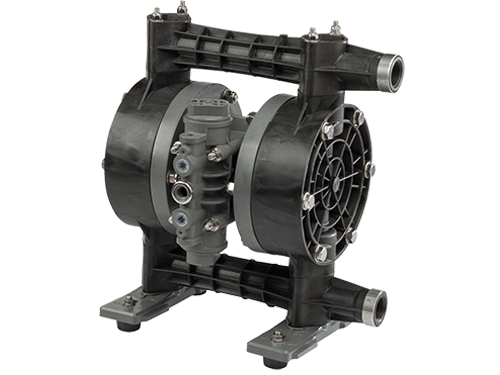

1 1/2″ TC-X400 Series

Maximum Flow Rate: 100.4 GPM (380 LPM)

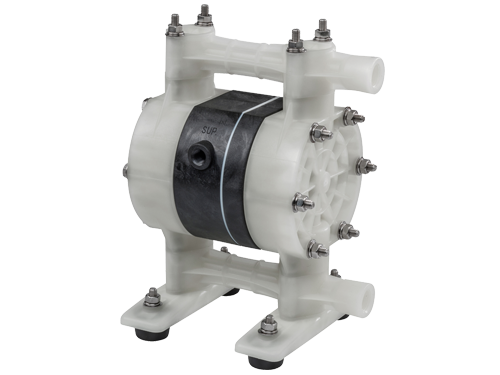

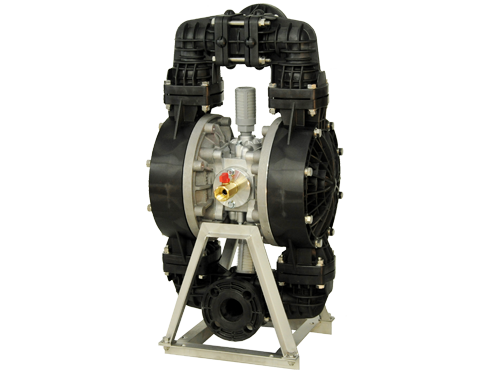

1 1/2″ TC-X401 Series

Maximum Flow Rate: 100.4 GPM (380 LPM)

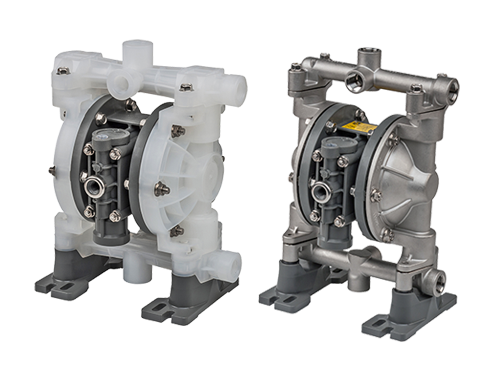

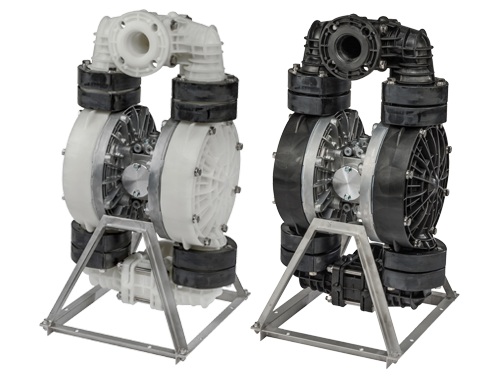

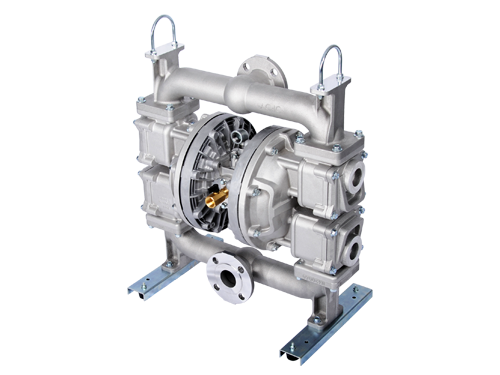

2″ TC-X500 Series Flap Valve Pumps

Maximum Flow Rate: 158.5 GPM (600 LPM)

In the land of fluid management, it’s crucial to prioritize efficiency, reliability and versatility. Whether it’s the chemical industry or the food and beverage sector, having the appropriate pump technology can significantly impact operations. Iwaki Air, a known name, in air-operated diaphragm pumps provides advanced solutions tailored to meet a variety of industry requirements.

What are Pneumatic Diaphragm Pumps?

Pneumatic diaphragm pumps, also known as air-operated double diaphragm (AODD) pumps, are positive displacement pumps that use compressed air as their power source. These pumps feature two diaphragms that movement to create a temporary chamber, for fluid intake and expulsion. Their efficient pumping mechanism makes them ideal for managing types of fluids including those, with viscosity, corrosive characteristics and solid particles.

What Makes Us Best Pneumatic Diaphragm Pumps Manufacturer?

Iwaki Air stands out in the market with its commitment to innovation, quality, and customer satisfaction. Here are some compelling reasons to choose Iwaki Air Pneumatic Double Diaphragm Pumps for your fluid handling needs:

- Superior Performance and Reliability: Iwaki Air’s Pneumatic Double Diaphragm Pumps are crafted to excel in environments showcasing performance. Their sturdy design guarantees lasting resilience reducing the need, for repairs and maintenance. These pumps are adept at managing chemicals, abrasive mixtures and viscous fluids making them a versatile choice, for various industrial uses.

- Versatile and Flexible Solutions: One of the key advantages of Iwaki Air pumps is their versatility. They can be used in various industries, including chemical processing, pharmaceuticals, food and beverage, water treatment, and more. Whether you need to transfer, dispense, or meter fluids, we have a solution tailored to your specific requirements. Their pumps can handle everything from thin, watery liquids to thick, viscous substances, ensuring optimal performance in any application.

- Energy-Efficient Operation: Energy efficiency is a critical consideration for businesses looking to reduce operational costs and environmental impact. Our pneumatic diaphragm pumps are designed with energy efficiency in mind. By utilizing compressed air effectively, these pumps minimize energy consumption while maintaining high levels of performance. This not only lowers operating costs but also contributes to a greener, more sustainable operation.

- Ease of Maintenance and Serviceability: Iwaki Air understands the importance of minimizing downtime and ensuring smooth operations. Their pneumatic diaphragm pumps are designed for easy maintenance and serviceability. With fewer moving parts and simple, straightforward construction, these pumps can be quickly disassembled and reassembled for routine maintenance or repairs. This ease of maintenance translates to reduced downtime and increased productivity for your business.

- Advanced Technology and Innovation: Innovation is at the core of Iwaki Air’s philosophy. Their pneumatic diaphragm pumps incorporate the latest advancements in pump technology to deliver superior performance and reliability. From advanced materials that enhance chemical resistance to smart monitoring systems that provide real-time performance data, we are committed to staying ahead of the curve and providing cutting-edge solutions to their customers.

Applications of Iwaki Air Pneumatic Diaphragm Pumps

Iwaki Air’s pneumatic diaphragm pumps are versatile and adaptable, making them suitable for a wide range of applications across various industries. Here are some key applications where these pumps excel:

- Chemical Processing: In the chemical industry, handling aggressive and corrosive fluids is a common challenge. Our pumps are designed to withstand the harshest chemicals, ensuring safe and efficient fluid transfer. They are ideal for applications such as chemical dosing, mixing, and transfer, providing reliable performance in even the most demanding environments.

- Pharmaceuticals: Pharmaceutical manufacturing requires precise and contamination-free fluid handling. Iwaki Air pneumatic diaphragm pumps meet the stringent standards of the pharmaceutical industry, offering clean and efficient fluid transfer solutions. They are suitable for applications such as liquid transfer, filtration, and filling, ensuring product integrity and consistency.

- Food and Beverage: In the food and beverage industry, hygiene and safety are paramount. Iwaki Air pumps are designed with food-grade materials and hygienic designs to meet the strictest sanitary standards. They are perfect for applications such as ingredient transfer, CIP (clean-in-place) systems, and packaging, ensuring the highest levels of cleanliness and product quality.

- Water and Wastewater Treatment: Water treatment facilities require reliable and efficient pumps for various processes, including chemical dosing, sludge transfer, and filtration. Iwaki Air pneumatic diaphragm pumps are up to the task, providing dependable performance and corrosion resistance. Their ability to handle abrasive and viscous fluids makes them ideal for wastewater treatment applications.

- Mining and Construction: In the mining and construction industries, durability and reliability are critical. Iwaki Air pumps are built to withstand tough conditions, making them suitable for dewatering, slurry transfer, and dust suppression applications. Their robust design ensures consistent performance in harsh environments, reducing downtime and maintenance costs.

Key Features of Iwaki Air Pneumatic Diaphragm Pumps

Iwaki Air double diaphragm pneumatic pumps are packed with features that set them apart from the competition. Here are some of the standout features that make these pumps a top choice for fluid handling applications:

- Chemical-Resistant Materials: Iwaki Air pumps are constructed from high-quality materials that offer excellent chemical resistance. This ensures compatibility with a wide range of fluids, including aggressive and corrosive chemicals, extending the lifespan of the pumps and reducing maintenance requirements.

- High Flow Rates and Pressure Capabilities: These pumps are designed to deliver high flow rates and handle substantial pressures, making them suitable for demanding applications. Whether you need to move large volumes of fluid quickly or maintain consistent pressure in a system, Iwaki Air pumps can meet your needs.

- Self-Priming and Dry Running Capabilities: Iwaki Air pneumatic diaphragm pumps are self-priming, meaning they can start pumping without the need for manual priming. Additionally, they can run dry without damage, providing flexibility and reliability in applications where fluid levels may fluctuate.

- Intrinsically Safe and Explosion-Proof Options: For industries dealing with flammable or hazardous materials, safety is a top priority. Iwaki Air offers intrinsically safe and explosion-proof pump options that meet the highest safety standards, ensuring safe operation in potentially dangerous environments.

- Compact and Portable Design: The compact and portable design of Iwaki Air pumps makes them easy to install and move as needed. This versatility is particularly beneficial in applications where space is limited or where the pump needs to be relocated frequently.

Investing in Iwaki Air double diaphragm pneumatic pumps means choosing a partner committed to your success. Experience the difference that quality, innovation, and customer focus can make in your operations. Contact Iwaki Air today to learn more about their range of pneumatic diaphragm pumps and discover how they can elevate your fluid handling processes to new heights.

Get Social