Built for Power, Built to Last

Global Provider of Air-Operated Double Diaphragm Pumps

WHY CHOOSE AN IWAKI AODD PUMP?

Iwaki Air AODD pumps are engineered for maximum utility. These air-operated diaphragm pumps are portable, as well as easy to install, operate, and maintain. With their infinitely variable flow rates and variable discharge pressures, these air diaphragm pumps can handle various fluids, including corrosive chemicals and flammable liquids. Iwaki Air AODD pumps can run dry, self-prime and dead-head without damaging the pump. Most importantly, these air-operated diaphragm pumps feature a lube-free air valve with a non-centering spring, which is specially designed to avoid stalling and is accessible for easy maintenance.

Being an experienced AODD pumps manufacturer, we understand the pumping challenges of different industries dealing with toxic, corrosive, and extremely sensitive fluids. Our AODD diaphragm pumps are built for power. A higher power output means the pump can operate with less applied air pressure compared with many competitor’s pumps – often outperforming pumps that may have a higher listed flow rate.

FIRST IN QUALITY

Iwaki Air understands the importance of quality and innovation. Total Quality Management is ingrained in the Iwaki Air brand of Air-Operated Double Diaphragm pumps, which are manufactured under stringent ISO 9001 standards. Quality is paramount in every aspect of the design, engineering and manufacturing of Iwaki Air AODD pumps. An industry-leading and innovative pilot valve design and superior non-lubricated air valve technology are key to Iwaki Air AODD pump’s renowned reliability. Quality is evident from the start, in the sourcing of raw materials, which come from well-known and reputable global suppliers. Careful selection of high-quality materials ensures exceptional chemical resistance compared to air-driven double diaphragm pumps made from inferior materials. Every air diaphragm pump is leak-tested to ensure years of reliable service.

FEATURES OF OUR AIR-OPERATED DOUBLE DIAPHRAGM PUMPS

Air Operated Double Diaphragm Pump

An Air-Operated Double Diaphragm pump (AODD) features two pumping chambers and flexible diaphragms and are reliable, as well as easy to maintain. The pumping action is created by feeding and venting the compressed air to chambers located on the diaphragm’s opposite sides. AODD diaphragm pumps are used for fluid transfer applications across industries. They are used for transferring slurries, sludge, sensitive fluids, and abrasives. As an AODD pumps manufacturer, we take pride in our offerings of standard and specialty AODD pumps, which may make the selection of these pumps challenging.

FAQ’s on Air-Operated Double Diaphragm Pumps

Air-operated double diaphragm pumps utilize flexible diaphragms to separate the fluid and compressed air supply. The diaphragms are driven by compressed air to minimize mechanical stress and improve their lifespan. The air valve system, which has two outlet and inlet valve balls, opens and closes as fluids pass through the pump.

The AODD pump starts the operation when the air distribution system directs the air to the air chamber and the diaphragm. The air is usually directed to the back side of the diaphragm, which moves the diaphragm toward the liquid chamber. In this process, the opposite diaphragm is pulled inward. The atmospheric pressure forces the fluid to reach the inlet manifold. This makes the liquid to flow into the liquid chamber, moving past the inlet valve ball.

Once the liquid chamber on one side of the AODD pump reaches capacity, compressed air is redirected to the back of the opposite diaphragm, causing it to pull away while the other is forced towards the liquid chamber. This process closes the intake valve ball and lifts the discharge valve ball off its seat, allowing the liquid to flow through the discharge manifold. The process is then repeated on the opposite side, with each diaphragm going through one discharge and one suction stroke before returning to its original position.

Major Components of Air-Operated Double Diaphragm Pumps

Diaphragms: The diaphragms are the heart of the air-operated double diaphragm pumps, responsible for the suction and discharge of fluid. They move back and forth to create the pumping action. Diaphragms are crafted from a range of materials, like rubber, Teflon or other elastomers, selected depending on their compatibility, with the liquid being pumped. Usually, pumps have two diaphragms linked by a rod. As air pushes one diaphragm the other is pulled, ensuring a co-ordinated motion.

Air Valve: The air valve regulates the flow of compressed air to each diaphragm managing the pumps movement. Two typical types of air valves are the spool valve and pilot valve which efficiently switch the airflow between diaphragms. This valve guarantees that one diaphragm receives air while the other releases it enabling the back-and-forth motion.

Chambers: The pump chambers are responsible, for pulling and pushing out the fluid. Each diaphragm operates within its chamber engineered to handle the pressure and characteristics of the pumped fluids, including abrasive or solid containing substances. When one diaphragm generates a vacuum in its chamber it draws fluid in while the other diaphragm expels fluid, from its chamber.

Check Valves: Check valves ensure that fluid flows in only one direction, preventing backflow and maintaining efficient pumping. Common types include ball valves, flap valves, and flat valves. The choice depends on the fluid characteristics and application requirements. There are typically four check valves in an air-operated double diaphragm pump, two at the inlet and two at the outlet of each chamber.

Manifolds: Manifolds connect the pump chambers to the inlet and outlet ports, guiding the fluid into and out of the air-operated double diaphragm pumps. They are created to reduce resistance to fluid and guarantee a flow. They can be set up in manner to meet installation needs. Manifolds are commonly crafted from materials that work well with the liquid being pumped, like steel, aluminum or plastic.

AODD pumps assure leak-free and smooth fluid transfer in most applications where they are used. This makes them an ideal choice for applications where challenging fluids may be involved.

The following are a few applications of Air-Operated Diaphragm Pumps

- Oil and Gas: Air-driven double diaphragm pumps are also known as double diaphragm pumps, used in the oil and gas industry for safe transfer of corrosive fluids without seals to prevent leaks and contamination.

- Mining: Portable and lightweight Air-operated pumps are utilized for mineral and ore extraction to handle high flow rates and prevent leaks. Their mobility allows easy site-to-site transport.

- Water and Wastewater Treatment: Air-operated diaphragm pumps are used extensively in water purification, chemical treatment, and sludge removal processes.

- Food and Beverage Processing: Our FDA compliant Air-operated Pumps are designed to maintain hygienic standards in food, beverage, and pharmaceutical industries, transferring fluids without altering taste or form and avoiding excessive mixing/shearing.

- Concrete Manufacturing: Air-operated diaphragm pumps are ideal for handling the highly abrasive materials common in concrete production. They ensure efficient mixing and transfer with minimum wear and tear, reducing maintenance costs and downtime.

- Chemical: These pumps are available in various materials, making them resistant to chemical corrosion and can handle a wide range of viscosities and temperatures. Their design prevents leaks and ensures the safe and efficient transfer of hazardous chemicals.

- Semiconductor: Air-operated diaphragm pumps are essential in the semiconductor industry due to their ability to handle ultra-pure chemicals without contamination. They maintain the integrity of the chemicals used in wafer fabrication and other processes, ensuring high-quality semiconductor products.

- Textiles and Carpet: Air-operated diaphragm pumps handle various viscosities and shear-sensitive fluids, ensuring consistent application of dyes and treatments without degradation. Their ability to transfer large volumes efficiently makes them ideal for large-scale textile and carpet manufacturing processes.

Iwaki Air provides a range of industrial AODD pumps, available in various sizes and materials. Through extensive testing and critical analysis, Iwaki Air has made significant breakthroughs in AODD pump diaphragm technology, resulting in more durable products that can withstand harsh fluids such as oil, chemicals, and acids. Additionally, Iwaki Air has pioneered new hygienic, FDA-compliant diaphragms with enhanced flex life and durability, making them ideal for sanitary applications and providing substantial savings in labor and downtime.

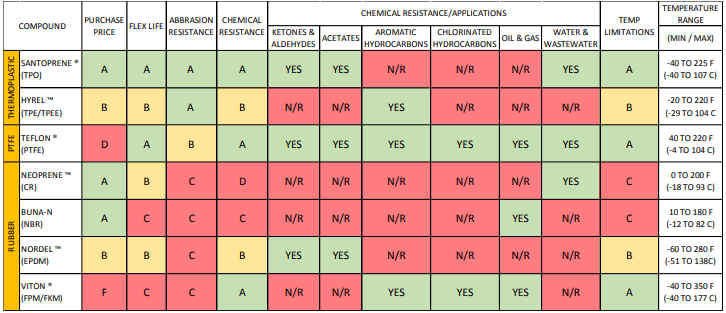

Over the years, a number of materials have been tested extensively for use in diaphragms in AODD pumps. These materials can be grouped into three primary families: Rubber, TPE (thermoplastic elastomer) and PTFE (Polytetrafluoroethylene or Teflon® ). Each family and the materials offer properties and attributes that make them suitable for different applications.

What is the suction pressure for Air-Operated Pumps?

The suction pressure of air-operated pumps may fluctuate based on factors, like the pump design, the pumped fluid type, and the application needs. Nonetheless there exist recommendations and usual ranges to consider:

- IwakiAir AODD pumps are able to suction lift up to 26.2’ when primed.

- Net Positive Suction Head Required (NPSHr): For proper operation, it is essential to ensure that the NPSHr of the pump is met. The NPSHr value is provided by the manufacturer and indicates the minimum pressure required at the suction port to avoid cavitation. This value varies based on the pump model and operating conditions.

Elastomer Properties and Limitations

Yes, AODD diaphragm pumps can cavitate under certain conditions. Cavitation occurs when the pressure in the pump falls below the vapor pressure of the liquid being pumped, causing vapor bubbles (or cavities) to form. These vapor bubbles are then carried into the higher-pressure regions of the pump, where they can collapse or implode, leading to noise, vibration, flow deficiency and potential damage to the pump components.

Damage to AODD pumps is usually less severe and costly compared to other types of pumps, primarily affecting diaphragms with occasional issues involving valves or the pump body. However, cavitation in AODD pumps can significantly increase operational costs.

Here are some common causes and preventive measures to avoid cavitation in AODD pumps:

Common Causes of Cavitation in AODD Diaphragm Pumps

Inadequate Net Positive Suction Head (NPSH): If the Net Positive Suction Head Available (NPSHa) is less than the Net Positive Suction Head Required (NPSHr) by the pump, cavitation can occur. NPSHr is provided by the pump manufacturer and should always be met or exceeded by the system’s NPSHa.

High Suction Lift: Excessive suction lift (the vertical distance between the pump and the fluid source) can reduce the pressure at the pump inlet, leading to cavitation.

Long or Restrictive Suction Piping: Long suction lines, sharp angles, undersized piping or too many fittings and valves can create friction losses, reducing the pressure at the pump inlet. Suction pipe should always be the same size or larger than the pump’s suction port. Suction filters should be un-restricted and inspected periodically.

High Fluid Temperature: Higher fluid temperatures increase the vapor pressure of the liquid, making it easier for cavitation to occur.

Viscous or Entrained Solids: Pumping highly viscous fluids or fluids with entrained solids can increase the suction pressure requirements and lead to cavitation if not properly managed.

Preventive Measures

Ensure Adequate NPSH: Verify that the NPSHa in your system meets or exceeds the NPSHr specified by the pump manufacturer. This can involve checking the system design and making necessary adjustments.

Optimize Suction Piping: Use appropriately sized suction piping, suction pipe should always be the same size or larger than the pump’s suction port. Minimize the length of the suction line, and reduce the number of fittings and valves to minimize friction losses.

Control Fluid Temperature: Maintain the fluid at a temperature that keeps its vapor pressure low, reducing the risk of cavitation.

Proper Pump Placement: Position the pump as close to the fluid source as possible to minimize suction lift and friction losses.

Regular Maintenance: Ensure the pump and suction line are free of blockages and that the pump components are in good condition to maintain optimal performance.

See an Iwaki AODD Pump in Action!

Find the Right AODD Pumps by Size

Iwaki Air pumps are designed to meet the demanding needs of various industries, providing reliable, efficient, and safe fluid handling solutions. Whether it’s precise chemical dosing, heavy-duty material transfer, or maintaining hygienic processing conditions, our pumps excel in diverse applications. Below are some of the key industries that benefit from our advanced pump technology:

Get Social