Quality, reliability, performance, and purity are requisites for high purity chemical production applications. Iwaki Air offers high-purity air-operated double-diaphragm (AODD) pumps that meet these requirements. All pumps are manufactured to the highest quality standards and are proven to perform in high purity applications. Our high-purity pumps are characterized by their robustness, lasting performance, as well as low maintenance costs.

Types of High Purity AODD Pumps

High purity chemicals are used in precise manufacturing processes across semiconductor and pharmaceutical industries. Managing these chemicals during the production and storage can be hazardous. The pumps used for chemical transfer can be prone to chemical attacks. Knowing this, we have designed high purity air diaphragm pumps, which assure lasting performance and greater stability as well as reliability during operations. The following are a few popular high purity AODD pumps available from Iwaki Air.

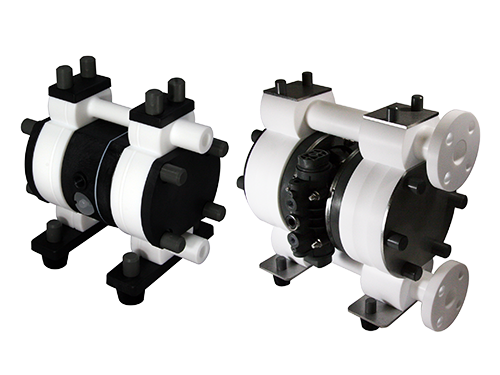

- High Purity AODD Pumps: These pumps are designed for use in cleanroom applications across the semiconductor industry. Our selection features TC-X TT Series pumps, which are available in 5 flow sizes in a wide range of options and accessories. These pumps feature non-lubricated technology and built-in design designed to resist material creep and minimize chances of leakage over time.

- Ultra High Purity Pumps: The TC-X TTD series of pumps come in six flow sizes. Our ultra high purity pumps are designed to transfer highly corrosive chemicals, in cleanroom environments during the production of semiconductors. Equipped with non-lubricated technology, these pumps are designed to ensure low particle counts. They help reduce the chances of metallic ion contamination during the process. These super high purity pumps are Class 100 clean room manufactured, tested, and double bagged.

We understand the stringent sanitation and quality fluid transfer requirements of the high purity and pharmaceutical industries. All materials for the pumps are carefully chosen and sourced from trusted manufacturers. Quality is incorporated in every phase of manufacturing. Contact us today to learn more about our high purity AODD pumps. Our experts would happily answer your inquiry and guide you with the right selection of high purity air diaphragm pumps.

Frequently Asked Questions About High Purity Pumps

What are High Purity Pumps and What Industries Require Them?

High purity pumps are specialty fluid handling equipment that ensures fluid integrity and purity in sensitive applications. They are widely utilized in industries such as pharmaceuticals, biotechnology, semiconductor manufacturing, and food and beverage processing. These pumps are critical for procedures where even minimal pollution might degrade product quality or pose a safety risk.

What are the Key Considerations When Selecting High Purity Pumps?

When selecting high purity pumps, several criteria should be considered, including the type of fluid being handled, flow rates, pressure requirements, temperature ranges, and compatibility with cleaning and sterilizing operations. To guarantee that the selected pump fits the unique needs of the application as well as industry standards, aspects such as reliability, maintenance requirements, and regulatory compliance must be carefully considered.

How Can High Purity Pumps Help Improve Process Efficiency and Product Quality?

High purity pumps reduce the risk of contamination-related concerns such product defects, batch rejections, and equipment damage by maintaining fluid purity and integrity. This can result in higher process efficiency, less downtime, and lower production costs. Furthermore, high purity pumps allow manufacturers to adhere to strict quality and safety standards, ensuring that their goods constantly fulfil regulatory criteria and client expectations.

Get Social