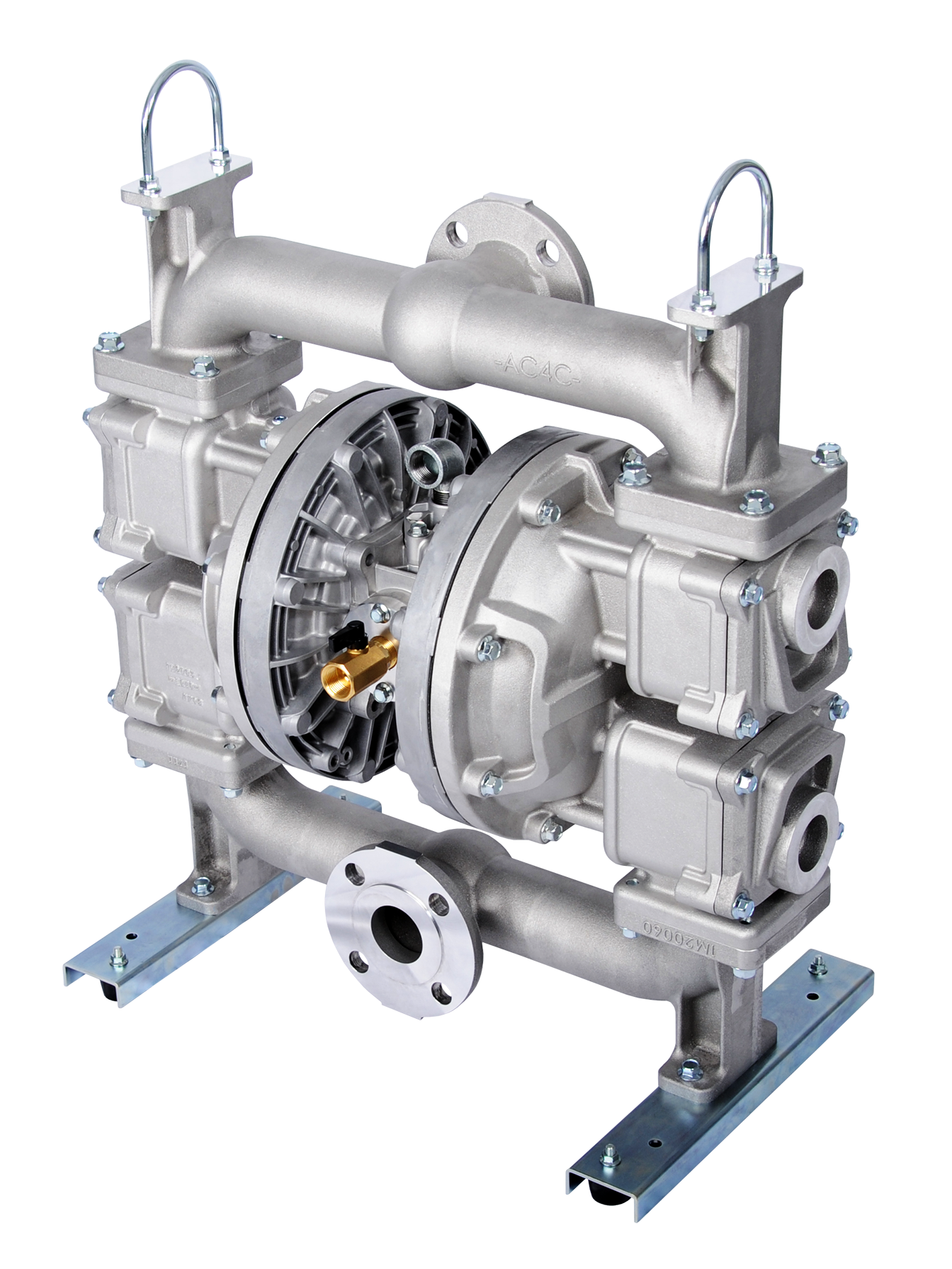

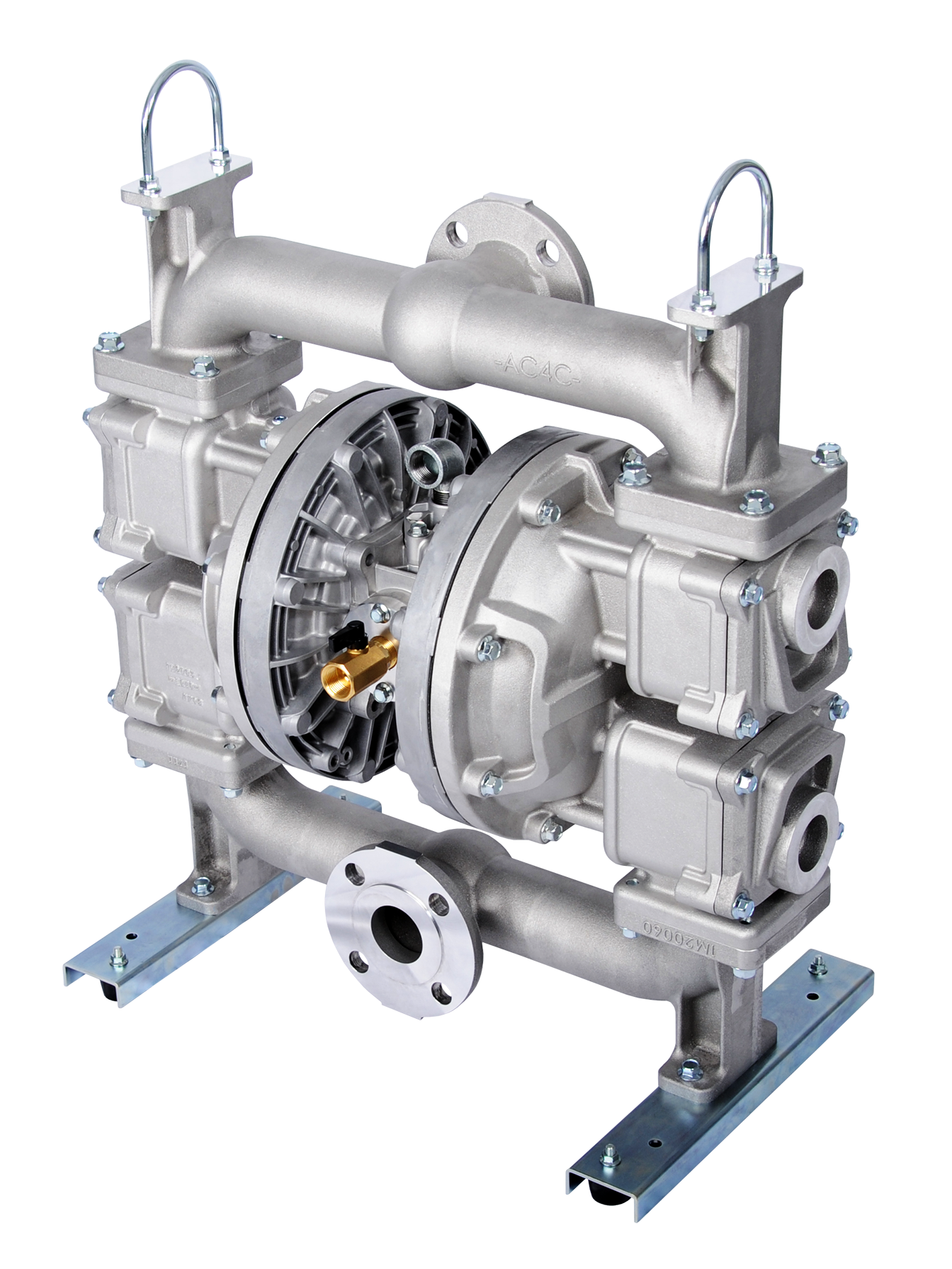

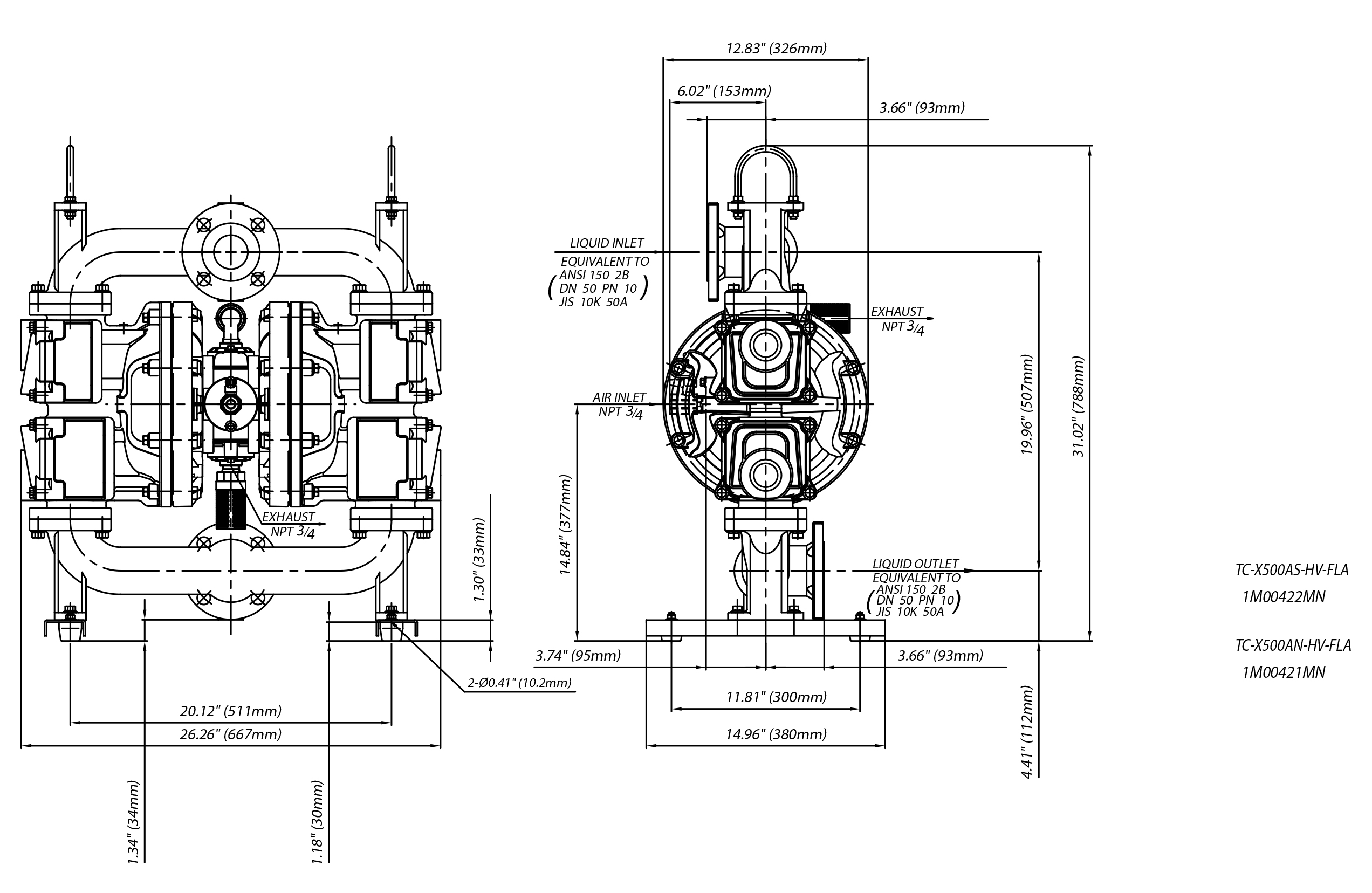

TC-X500 Series Metallic Flap Valve Pumps![]()

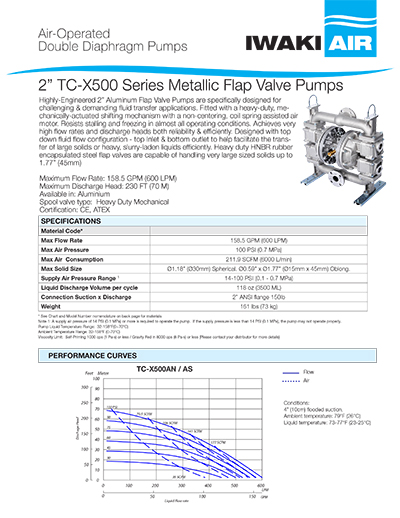

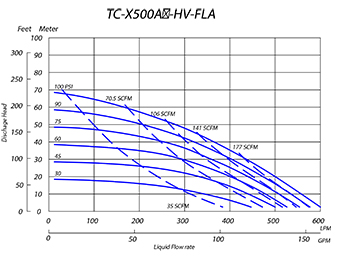

Specifications of 2” Aluminum AODD Flap Valve Pumps

|

|

How Flap Valve Diaphragm Pumps Work?

The highly-engineered 2” aluminum heavy duty flap valve diaphragm pumps operates on the principles of a flap valve diaphragm pump. The flap valve diaphragm pump utilizes a unique mechanism involving a heavy-duty, mechanically-actuated shifting mechanism with a non-centering, coil spring-assisted air motor. This mechanism allows the pump to efficiently transfer fluids even in challenging conditions. Heavy duty HNBR rubber encapsulated steel flap valves ensure large solids can pass through without clogging.

Key features of Flap Valve Air Diaphragm Pumps

Top-Down Fluid Flow Configuration: Unlike traditional pumps that may have a bottom inlet, this pump is designed with a top inlet and bottom outlet configuration. This design choice is particularly advantageous for applications involving the transfer of large solids or heavy, slurry-laden liquids. By allowing fluid to flow from the top down, the pump can efficiently handle substances that may otherwise cause clogging or flow issues in pumps with different configurations. This feature enhances overall efficiency and reliability in challenging fluid transfer scenarios.

Heavy Duty HNBR Rubber Encapsulated Steel Flap Valves: The pump is equipped with flap valves made of heavy-duty materials: HNBR rubber encapsulated steel. This construction ensures durability and resilience, even when handling corrosive or abrasive fluids. The flap valves are designed to seal tightly and withstand high pressure, effectively preventing backflow and maintaining smooth operation. Additionally, their ability to handle very large-sized solids up to 1.77” (45mm) further underscores their suitability for demanding applications where debris or particulate matter may be present. Valves can be inspected and changed via an external cover.

These key features of our flap valve air diaphragm pumps collectively contribute to the pump’s exceptional performance and reliability in challenging fluid transfer applications. Whether it’s dealing with abrasive slurries, viscous fluids, or large solids, the pump’s top-down fluid flow configuration and heavy-duty flap valves ensure efficient operation and minimal downtime, making it a preferred choice for industries requiring robust fluid transfer solutions.

Applications of AODD Flap Valve Pumps

AODD Flap Valve Pumps, with their robust construction and efficient fluid transfer capabilities, find diverse applications across various industries:

Food Processing: In food plants, AODD Flap Valve Pumps are employed for transferring large solids, abrasive slurries, and viscous liquids. Their ability to handle a wide range of sizes and resist clogging makes them indispensable in food processing operations.

Mining: In the mining industry, it is use for a multitude of tasks, including pumping mine dewatering, transporting slurries containing abrasive particles, and transferring chemical reagents for mineral processing. Their rugged design and ability to handle abrasive materials make them ideal for the harsh conditions encountered in mining operations.

Wastewater Treatment: It plays a crucial role in wastewater treatment facilities for transferring sewage, sludge, and other wastewater materials. They are capable of handling solids-laden liquids and viscous slurries commonly found in wastewater treatment processes.

Dewatering: AODD Flap Valve Pumps are ideal for dewatering applications where solids are present and unexpected objects may be in the fluid.

Get Social