No Power – No Problem

One of the best benefits of an air operated double diaphragm pump is that it runs off of shop air, not electricity. There is no need to hire an electrician, just drag an air hose to the pump and fire it up. This flexibility along with forgiving hydraulics of AODD pumps make it the best choice for utility applications.

One of the best benefits of an air operated double diaphragm pump is that it runs off of shop air, not electricity. There is no need to hire an electrician, just drag an air hose to the pump and fire it up. This flexibility along with forgiving hydraulics of AODD pumps make it the best choice for utility applications.

100% Bolted Construction

BACK TO BASICS – VARIABLE FLOW RATE

Controlling the flow an AODD pump is as simple as adjusting the amount of air that is entering the pump. The less air consumed – the lower the flow rate. While most operators use a mechanical air valve to adjust the flow manually an electro pneumatic valve can be used to do so electronically. Look for more information on our E series electro pneumatic valve in an upcoming newsletter.

BACK TO BASICS – DRY-RUNNING

Do you have customers that constantly replace mechanical seals due to dry running?

The inherent design of an AODD pump allows for intermittent dry running without damage. Of course every pump manufacturer frowns upon running their product without liquid within it, the internal design of an air operated diaphragm pump allows run dry without causing damage. The fear of destroyed mechanical seals found in centrifugal pumps is eliminated when using an AODD pump.

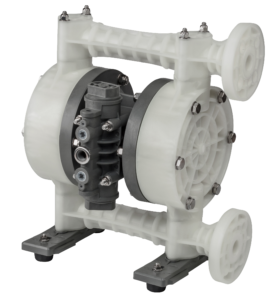

PRODUCT SPOTLIGHT

Standing 3 ft. tall and weighing over 100 lbs., the TC-X800 series is the flow rate champion of the Iwaki Air AODD family of pumps. The TC-X800 metallic and TC-X801 non-metallic pumps can provide flows over 200 gpm and produce 125 PSI !!!! When faced with applications requiring a ridiculous amount of flow, this is the product to select. 3” pumps are on the shelf in Holliston, MA and have a list price hundreds of dollars less than most competitive brands.

BACK TO BASICS – SELF-PRIMING

Air operated double diaphragm pumps have many great benefits. Perhaps the best is their ability to self-prime. The Iwaki TC-X series can lift up to 18 ft. dry and over 26 ft. when primed! Many applications require suction lift that most centrifugal pumps can not achieve. The inherent feature of self priming in Iwaki AODD pumps is a great solution in these circumstances.

Check out all of our self-priming capabilities on the distributor site.

Product Demo Sales Tools Available for Channel Partners

IWAKI AIR TECH TIPS

Slow the Pump Down to Prime

AODD pumps are popular when self-priming is required. Creating a low-pressure zone — less than the atmospheric pressure of 14.7 psi — inside the fluid bowls is how the AODD pump draws fluid. If air pressure supplied to the pump is too high, the pump will change over too quickly and there will not be enough time for the fluid to be drawn into the pump.

To solve this priming issue in a matter of seconds, slow down the pump by using the air regulator to decrease the air pressure entering the air valve. Once the pump speed has been reduced and the fluid has had enough time to enter the pump, increase the air pressure and operate the pump at a faster speed.

PRODUCT NEWS

- Iwaki AIR introduced full line of 1-1/2″ – 3″ Sleeve & Spool configured pumps (TCX-401, 501, 801)

- Iwaki AIR introduced “best-in-class” Flap Valve Pumps

Get Social