Recent Articles on AODD Pumps and Markets

How Air-Operated Diaphragm Pumps Handle Viscous and Abrasive Fluids

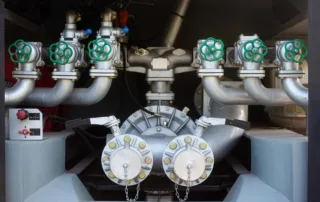

Air-operated diaphragm pumps (AODD pumps) have become indispensable in industries that handle challenging fluids, including those that are highly viscous or contain abrasive particulates. Their ability to transfer such materials without compromising performance or durability makes them a preferred choice for numerous industrial applications. Air-operated diaphragm pumps (AODD pumps) function using compressed air as their power source. Unlike electric-driven pumps, they do not rely on motors or gears, making them highly versatile for handling various challenging fluids, including viscous and abrasive materials. These pumps operate through a reciprocating motion, where two flexible diaphragms move back and forth inside the pump housing. The movement is driven by an [...]

The Impact of Turbulence on AODD Pumps and How to Mitigate It

AODD pumps are very versatile, highly reliable, and used in a wide range of industries from chemical processing to wastewater treatment. With their viscous, abrasive, and corrosive handling capability, they become irreplaceable in their field of operation. However, like all pumps, operational challenges do occur with AODD pumps, and one of the most serious involves turbulence. Minimizing the consequences of turbulence in AODD pumps requires understanding how it happens, along with strategies to minimize its effects and ensure continued optimal performance, pump longevity, and lower maintenance costs. What is Turbulence? Actually, turbulence can be best described as a condition of fluid flow wherein there is chaotic change [...]

A Guide to AODD Pump Accessories for Better Performance

Air-Operated Double Diaphragm (AODD) pumps are highly versatile, widely used in industries for their reliability and able to handle a wide variety of fluids. However, to ensure they perform optimally, the right accessories are crucial. These pumps operate using compressed air to move two diaphragms that, in turn, move the fluid through the pump. Their simplicity, coupled with their ability to handle everything from viscous fluids to abrasives, makes them a go-to choice in sectors like chemical processing, food and beverage, mining, and wastewater treatment. While AODD pumps are robust and can withstand harsh conditions, adding the right accessories can significantly boost their efficiency and lifespan. When [...]

Custom vs. Off-the-Shelf Air-Drive Pumps: Finding the Best Fit for Your Needs

When purchasing air operated diaphragm pumps for industrial purposes, you usually have a hard choice: whether to decide on an exclusively custom-built pump designed only for your needs or an off-the-shelf model, readily available and designed to meet the general industry requirements. This choice is indeed not a simple one and can affect your performance, cost, and efficiency to a great deal. Custom as well as off-the-shelf air driven pumps have their advantages and disadvantages, so selecting the right one would depend on an in-depth understanding of your application, industry-specific demands, and long-term operational goals. Each of these will affect not only the short-term budget but also [...]

How Sanitary Diaphragm Pumps Ensure Safe and Efficient Liquid Transfer

The pharmaceutical, food and beverage, biotechnology, and cosmetic industries require fast, efficient, reliable, and sanitary liquid transfer. In these industries, there has been an increasingly high demand for the maintenance of product integrity without contamination. That is where the sanitary diaphragm pumps show their value. These pumps are designed to safely transfer liquids while ensuring the process is not only efficient but also up to stringent hygiene standards. Let's understand the inner mechanics of the sanitary diaphragm pumps, how they work, and why they are indispensable in industries reliant on cleanliness and efficiency. What is a Sanitary Diaphragm Pump? A sanitary diaphragm pump is a type of [...]

What Affects Compressed Air in Air Diaphragm Pump and How to Manage It

Air diaphragm pumps are versatile and reliable mechanisms used in various industries involved in the transferring fluids and handling abrasive, and corrosive materials. The pump operates by using compressed air to drive a diaphragm mechanism through a pumping action. Compressed air demand is required to be well understood and managed for the optimal performance, efficiency, and longevity of air diaphragm pumps. Compressed air serves as the driving force behind the movement of the diaphragms within the pump. The effectiveness of this process hinges on several key factors, including the pump’s size, the nature of the fluid being pumped, and the operational conditions. Each of these elements can [...]

Get Social