Iwaki Air’s specialty AODD pumps are designed to meet the requirements of critical fluid applications across food and beverage, pharmaceutical production, and other industries. Our selection features a wide range of specialty series AODD pumps, from FDA pumps to high-pressure pumps to drum pumps and more. They can be used to transfer fluids of different viscosities and chemistries. Browse our selection to find the right pump that meets your needs!

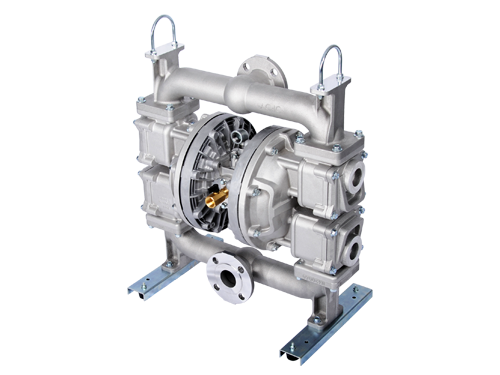

2″ TC-X500 Series Flap Valve Pumps

Maximum Flow Rate: 158.5 GPM (600 LPM)

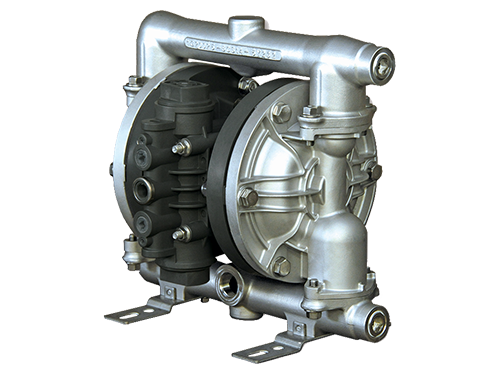

1 1/2″ TC-X401 Series

Maximum Flow Rate: 100.4 GPM (380 LPM)

1 1/2″ TC-X400 Series

Maximum Flow Rate: 100.4 GPM (380 LPM)

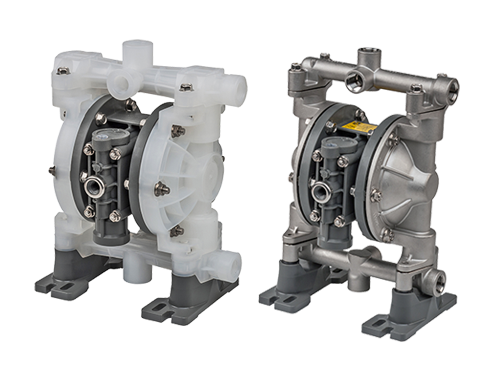

3/8″ TC-X100/101 Series

Maximum Flow Rate: 6.1 GPM (23 LPM)

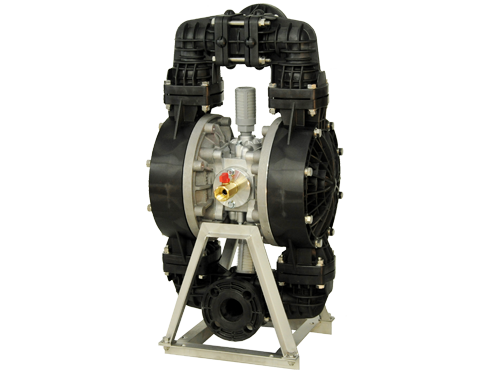

Specialty Pumps: Powder Pumps

Portable Powder Pumps Specially designed and engineered [...]

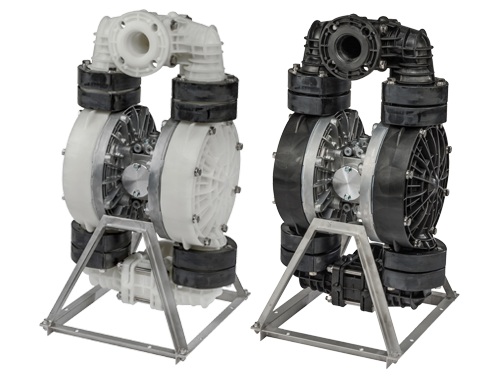

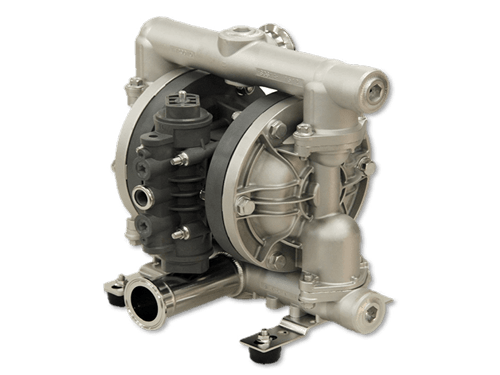

Specialty Pumps: FDA Compliant

¼”, 3/8”, ½”, ¾”, 1”, 1 ½” 2” & 3” Stainless Steel Pump Models

Drum Pumps

Available in a range of sizes and materials suitable for pumping directly from 55 gallon drums

Types of Specialty Diaphragm Pumps Offered by Iwaki Air

We offer an extensive selections of specialty diaphragm pumps that you can choose from.

- FDA Pumps: These pumps feature FDA-compliant sanitary flange fittings and stainless steel wetted parts. Our FDA pumps are engineered for consistent performance in beverage and food processing, cosmetic, chemical and pharmaceutical applications where USDA, 3A, and EDHG certifications may not be required.

- Flap Valve Pumps: Flap valve pumps are specialty AODD pumps designed for challenging and demanding applications. The pump has a top-down fluid flow configuration with a bottom outlet and top inlet. This configuration helps transfer fluids laden with heavy and large solids and slurry-laden liquids. Flap valve pumps are capable of handling very large sized solids up to 1.77” (45mm).

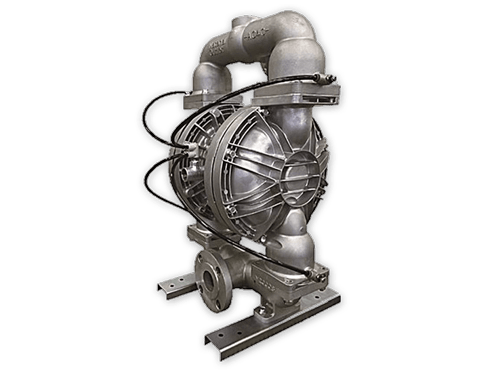

- High-Pressure Pumps: These pumps use standard air inlet pressure to produce double liquid discharge pressure. Our 2:1 high-pressure AODD pumps are ideal for applications where high liquid pressures are needed to withstand system pressures.

- Powder Transfer Pumps: As the name suggests, these pumps are designed to transfer dry, fine, and low-bulk powders like powder coatings, pigments, carbon black, talc, toners, fumed silica, and powdered plastics. Our portable powder transfer pumps assure a dust-free work environment. Our portable powder transfer pumps eliminate the requirement for heavy lifting and intensive physical labor.

- Electronically Actuated Pumps: These pumps feature an electronically actuated air switching mechanism. They can be easily integrated into process machinery and control systems. These pumps can run dry, as well as transfer liquid slurries. The advanced features enable pump controllability and allow remote monitoring.

- Drum Pumps: The pumps are designed to be used with 55-gallon drums. Our drum pumps transfer different types of liquids, including solvents, oils, lubricants, waste liquids, paints, diesel, and inks.

We understand challenging fluid transfer requirements across many industries. Our specialty series AODD pumps are designed to withstand these challenges. You can choose from plastic and metal fluid sections, as well as elastomers that can easily handle abrasive and corrosive fluids. Feel free to contact our team of experts today to discuss your application requirements.

Specialty Pumps Tailored to Your Application

Specialty pumps offered by Iwaki Air are available in a variety of flow rates and sizes. Each Iwaki Air’s speciality pump can be modified to meet your specific fluid transfer needs. Choose from a variety of diaphragm materials, casing styles, and accessories. Find metal or non-metallic liquid housings that can withstand any fluid, including corrosives and abrasives. With unrivalled performance, dependability, and versatility, our pumps are the pinnacle of engineering perfection, allowing you to overcome obstacles and achieve remarkable efficiency in different applications. Speciality pumps are essential across various industries due to their tailored applications:

Chemical Processing: In chemical industry they handle corrosive fluids in a safe manner, ensuring process integrity. These pumps are frequently built with corrosion-resistant materials to survive hostile chemical conditions.

Oil & Gas: The oil and gas sectors rely on specialty pumps to handle high-pressure situations during drilling, extraction, and transportation. They are also designed to handle abrasive fluids used in these operations.

Food & Beverage: Speciality pumps utilizes in Food & Beverages to maintain sanitary conditions and handle products with varying viscosities delicately. Hygienic designs ensure compliance with safety regulations, while pumps with low-shear features preserve product quality.

Pharmaceuticals: Speciality pumps are required for sterile processing and precise dosage of active components in pharmaceutical industry. They are critical components of clean-in-place systems, ensuring that equipment is clean between production cycles.

The Power of Speciality Pumps

Customized Solutions: We understand that each industry, process, and application presents its unique set of issues and requirements. That’s why our speciality pumps aren’t just off-the-shelf items; they’re custom-made solutions tailored to your exact specifications. Whether you’re working with corrosive fluids, abrasive materials, or severe temperatures, our professional engineers will collaborate with you to create a pump that’s appropriate for the job.

Optimized Performance: We do not tolerate mediocrity. Our speciality pumps are designed to give exceptional performance in even the most demanding settings. With sophisticated design features, cutting-edge materials, and precision production, our pumps provide optimal efficiency, uptime, and performance across a wide range of applications.

Enhanced Efficiency: In today’s competitive landscape, efficiency is key. Our speciality pumps are more than simply tools; they are strategic assets that help to streamline your processes, reduce waste, and increase productivity. We help you achieve new levels of efficiency and profitability by leveraging the most recent pump technology breakthroughs, providing you a competitive advantage in your sector.

Unrivalled Reliability: When it comes to vital processes, dependability is unavoidable. That is why our specialty pumps are designed to last, with durable construction, strong components, and stringent quality control procedures. Whether you’re running a 24-hour manufacturing line or working in the roughest settings, you can rely on our pumps to give consistent performance every time.

Get Social