Air Operated Double Diaphragm (AODD) fluid transfer pumps are commonly used in transfer applications and can handle a wide range of liquids such as sludges, slurries, abrasive, and shear sensitive fluids. Although they are durable, dependable, and simple to maintain, they can be noisy, prone to icing, and are typically used on low pressure applications.

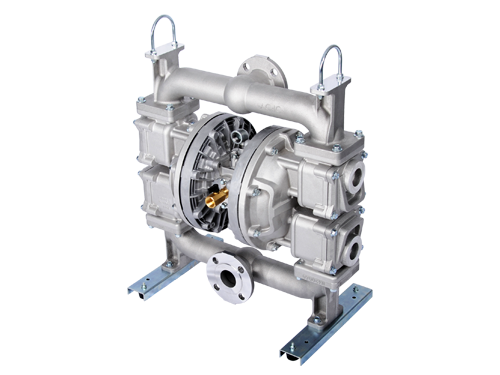

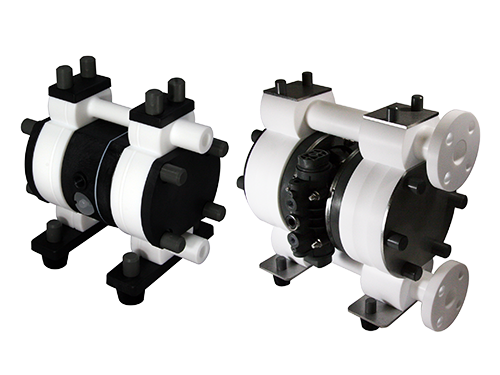

AODD pumps are comprised of two pumping chambers that are filled and expelled alternately using flexible diaphragms. The pumping motion is created by alternately feeding compressed air to and venting from air chambers on opposite sides of the diaphragms.

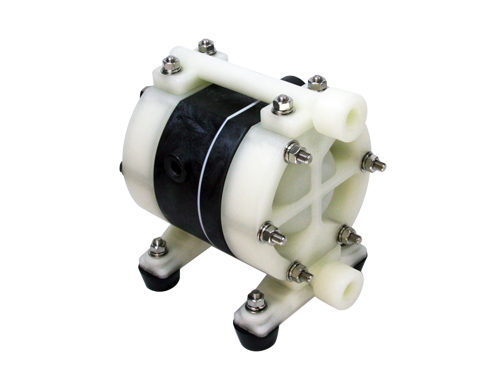

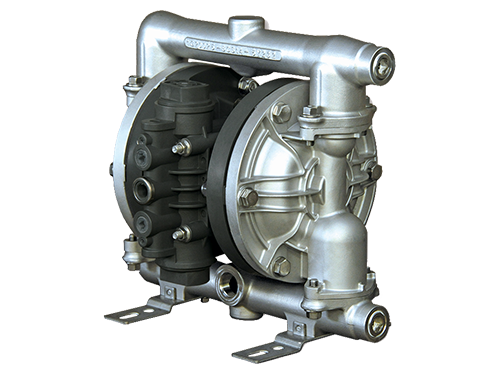

3/8″ TC-X100/101 Series

Maximum Flow Rate: 6.1 GPM (23 LPM)

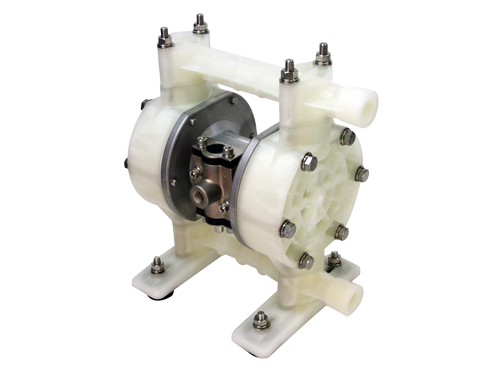

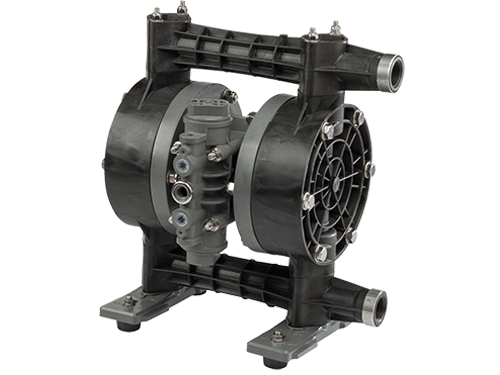

1 1/2″ TC-X400 Series

Maximum Flow Rate: 100.4 GPM (380 LPM)

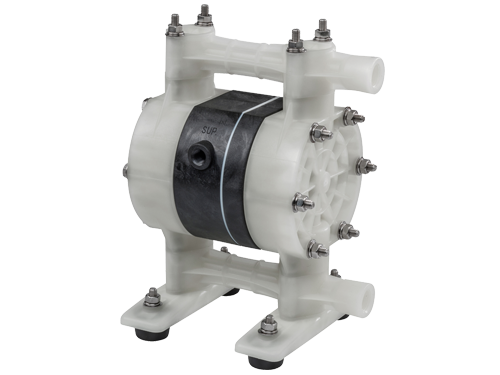

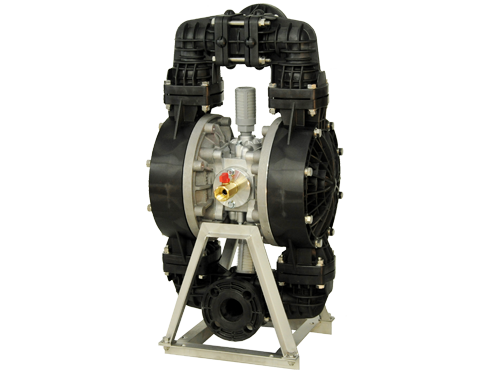

1 1/2″ TC-X401 Series

Maximum Flow Rate: 100.4 GPM (380 LPM)

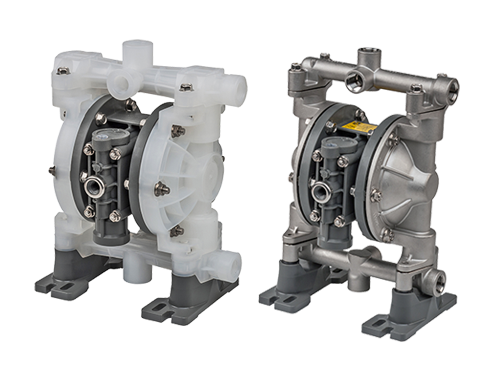

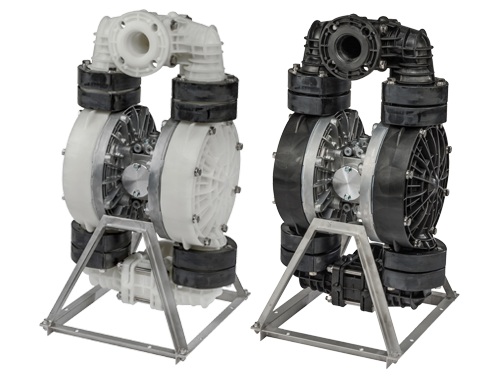

2″ TC-X500 Series Flap Valve Pumps

Maximum Flow Rate: 158.5 GPM (600 LPM)

Understanding AODD Fluid Transfer Pumps

Understanding the intricacies of AODD fluid transfer pumps is essential to appreciate their remarkable functionality and adaptability across various industries. Let’s understand the mechanics and versatility of these pumps:

Dual-Diaphragm Mechanism: AODD fluid transfer pumps operate on a simple yet ingenious principle. They consist of two flexible diaphragms, each housed within a pump chamber and connected to a common shaft. Compressed air alternately pressurizes and depressurizes the chambers, causing the diaphragms to flex and create suction and discharge strokes. This unique dual-diaphragm design enables the pumps to handle a wide range of fluids, from thin solvents to viscous slurries, with ease and efficiency.

Versatile Fluid Handling: One of the key advantages of AODD fluid transfer pumps is their ability to handle a diverse array of fluids, including corrosive chemicals, abrasive slurries, viscous liquids, and shear-sensitive materials. The pumps can accommodate varying viscosities, temperatures, and compositions, making them suitable for applications across multiple industries.

Self-Priming Capability: A notable feature of AODD fluid transfer pumps is their self-priming capability, which allows them to evacuate air from the suction line and create a vacuum to draw fluid into the pump chamber. This eliminates the need for manual priming and enables the pumps to start and operate efficiently even when the fluid source is located below the pump level. The self-priming ability makes them ideal for applications where a reliable suction lift is required, such as in remote or inaccessible locations.

Dry-Run and Stall-Free Operation: Another advantage of AODD fluid transfer pumps is their ability to operate under challenging conditions, including dry-run and stall situations. The inherent design of the pumps, with flexible diaphragms that can accommodate variations in pressure and flow, ensures smooth and continuous operation without damage or performance degradation.

Ease of Maintenance: AODD fluid transfer pumps are known for their simplicity and ease of maintenance. With fewer moving parts and a straightforward design, these pumps are easy to install, operate, and service. Routine maintenance tasks, such as diaphragm replacement or valve inspection, can be performed quickly and efficiently, minimizing downtime and maximizing productivity. Additionally, many AODD fluid transfer pumps feature modular construction, allowing for easy access to internal components and simplified troubleshooting.

Applications of Fluid Transfer Pumps

AODD fluid transfer pumps are not confined to a single industry; rather, they serve as versatile workhorses across a multitude of sectors. Let’s dive into the diverse applications of these pumps across industries:

Chemical Industry: In the chemical industry, where the handling of corrosive, abrasive, and volatile substances is commonplace, AODD fluid transfer pumps shine as reliable and robust solutions. From transferring acids, solvents, and caustic chemicals to dosing additives and reagents with precision, these pumps offer the durability and chemical resistance necessary to withstand the demands of this challenging environment.

Pharmaceutical and Biotechnology: The pharmaceutical and biotechnology sectors demand precision and purity in fluid handling to maintain product integrity and regulatory compliance. Fluid transfer pumps excel in this regard, offering gentle yet accurate transfer of delicate formulations, active pharmaceutical ingredients (APIs), and biologics.

Food and Beverage: From breweries and dairies to soft drink bottling plants and food processing facilities, the food and beverage industry relies on AODD fluid transfer pumps for safe and hygienic fluid transfer. These pumps are adept at handling a wide range of products, including viscous syrups, dairy products, sauces, and flavorings, without compromising on quality or sanitation standards.

Manufacturing and Automotive: In manufacturing and automotive applications, AODD fluid transfer pumps play a vital role in various fluid transfer tasks, such as transferring lubricants, coolants, hydraulic fluids, and waste oils. Their ability to handle abrasive fluids and withstand rugged operating conditions makes them indispensable in metalworking, machining, painting, and assembly processes.

Environmental and Wastewater Management: AODD fluid transfer pumps are instrumental in environmental and wastewater management applications, where the safe and efficient transfer of fluids is essential for pollution control and remediation efforts. These pumps are used for transferring chemicals in water treatment processes, dosing additives for pH adjustment, and handling sludges and effluents in wastewater treatment plants.

The Iwaki Air Advantage

When it comes to AODD fluid transfer pumps, Iwaki Air sets itself apart through a combination of pioneering innovation, unparalleled quality, and a commitment to tailored solutions. Let’s explore the facets that constitute the Iwaki Air Advantage in greater detail:

Pioneering Innovation: At Iwaki Air, innovation is not just a buzzword; it’s a way of life. We pride ourselves on pushing the boundaries of pump technology, constantly seeking out new avenues for improvement and refinement. Our dedicated team of engineers and researchers are at the forefront of innovation, leveraging the latest advancements in materials science, fluid dynamics, and manufacturing techniques.

Unmatched Quality: Quality is the cornerstone of everything we do at Iwaki Air. From the initial design phase to the final product assembly, we adhere to the highest standards of quality and craftsmanship at every step of the process. Each component of our AODD fluid transfer pumps is subjected to rigorous testing and inspection to ensure maximum reliability and durability. Iwaki Air is an ISO 9001 accredited company.

Tailored Solutions: We understand that every application is unique, and that one-size-fits-all solutions simply won’t cut it in today’s complex industrial landscape. Whether you require a pump with special materials of construction to handle corrosive fluids, or a custom configuration to accommodate space constraints in your facility, our team of experts will work closely with you to develop a solution that meets your exact specifications.

At Iwaki Air, we believe that true value lies in providing solutions that are tailored to the individual needs of our clients, and we’re committed to going above and beyond to deliver exactly that.

Get Social