Ball Guides

Ball Guides are fully independent and modular, designed to protect the body components of the AODD pump from unnecessary damage. As part of regular AODD pump maintenance, if worn out, they can be easily and inexpensively replaced during normal pump service without needing to replace an entire set of pump chambers or manifolds.

Ball Seats

Ball Seats are modular and can be easily replaced if worn out. As part of a comprehensive AODD pump maintenance guide, ball guides and seats can easily ne replaced during normal servicing.

Spool Valve

The Spool Valve is outside accessible and can be removed by hand within a few seconds. Instead of replacing the entire valve, it is usually possible to just change the Ekanol Seal Rings (5). The Spool Valve is 100% lubrication-free, so no grease or oil is required under normal operating conditions. This feature simplifies troubleshooting Iwaki Air pumps when valve issues arise.

Spool Sleeve

The Spool Sleeve is modular, replaceable, and 100% outside accessible. It is manufactured from an extremely hard-wearing and smooth material, allowing for an extended life expectancy. The sleeve is designed to protect the Air Motor Assembly from unnecessary abrasion damage, which is a key consideration in AODD pump troubleshooting.

Pilot Valves

Although considered a non-wearing component, the pilots may occasionally need to be changed. During AODD pump maintenance, it’s important to note that they are fully modular and operate independently. Each valve is contained within a hard-wearing and replaceable plastic seat, protecting the Air Motor Assembly from wear and tear.

Throat Bearings

The removable Throat Bearings contain and stabilize the Center Rod and are made from hard-wearing plastic. These bearings protect the Center Rod and the pump’s Air Motor Assembly from unnecessary wear and tear, which is crucial during pneumatic pump maintenance.

Diaphragms

Diaphragms are usually the most worn component and are available in a range of different materials. Regular inspection of the diaphragms is essential for thorough AODD pump troubleshooting and maintenance.

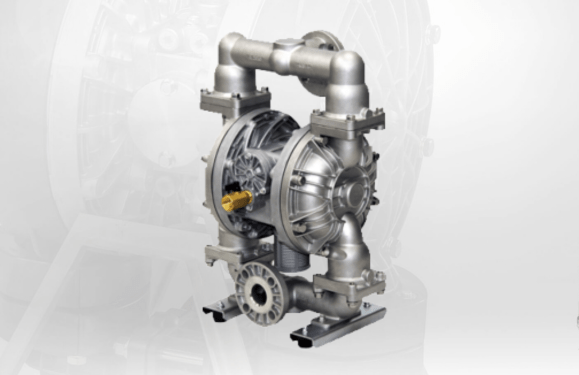

Maintenance Features Built into every Iwaki Air Pump

- Pumps are bolted and can be easily and quickly disassembled and reassembled.

- All wearing surfaces are modular and all wear parts are replaceable.

- Extensive use of high-tech abrasion resistant plastics and metals.

- No special tools are required for service.

- Pumps are non-lubricated.

- Air motor is outside accessible.

- Pumps are fitted with an air motor reset switch.

- Pumps can be easily torqued and re torqued over time.

- All liquid mating surfaces are machined.

Frequently Asked Questions

What is the importance of Ball Guides in AODD pump maintenance?

Ball Guides are crucial as they protect the pump’s body components from unnecessary damage. During routine AODD pump maintenance, these guides can be easily and cheaply replaced without needing to replace entire pump chambers or manifolds, ensuring the longevity and efficiency of the pump.

How often should Ball Valves and Ball Seats be inspected?

Ball Valves and Ball Seats should be inspected regularly as part of a comprehensive pneumatic pump maintenance routine. The frequency of inspection depends on the operating conditions, but regular checks help identify wear and allow for timely replacement to maintain optimal pump performance.

What makes the Spool Valve maintenance-friendly?

The Spool Valve is designed for ease of maintenance; it is outside accessible and can be removed by hand within seconds. Instead of replacing the entire valve, only the Ekanol Seal Rings may need to be replaced, which simplifies AODD pump troubleshooting and reduces maintenance costs.

Why is the Spool Sleeve considered durable?

The Spool Sleeve is made from extremely hard-wearing and smooth material, which extends its life expectancy. It is modular, replaceable, and protects the Air Motor Assembly from abrasion, making it a vital component in long-term AODD pump maintenance.

Get Social