Iwaki Air provides a range of industrial AODD pumps, available in various sizes and materials. Through extensive testing and critical analysis, Iwaki Air has made significant breakthroughs in AODD pump diaphragm technology, resulting in more durable products that can withstand harsh fluids such as oil, chemicals, and acids. Additionally, Iwaki Air has pioneered new hygienic, FDA-compliant diaphragms with enhanced flex life and durability, making them ideal for sanitary applications and providing substantial savings in labor and downtime.

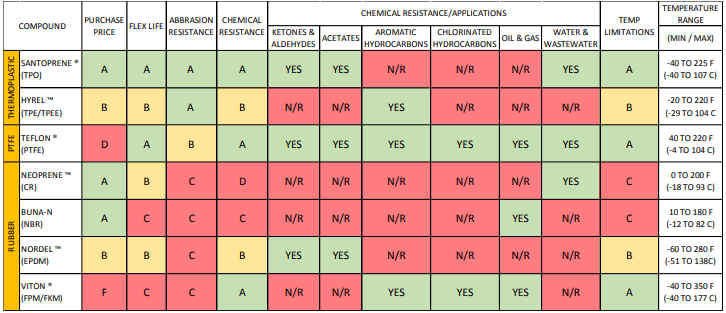

Over the years, a number of materials have been tested extensively for use in diaphragms in AODD pumps. These materials can be grouped into three primary families: Rubber, TPE (thermoplastic elastomer) and PTFE (Polytetrafluoroethylene or Teflon® ). Each family and the materials offer properties and attributes that make them suitable for different applications.

What is the suction pressure for Air-Operated Pumps?

The suction pressure of air-operated pumps may fluctuate based on factors, like the pump design, the pumped fluid type, and the application needs. Nonetheless there exist recommendations and usual ranges to consider:

- IwakiAir AODD pumps are able to suction lift up to 26.2’ when primed.

- Net Positive Suction Head Required (NPSHr): For proper operation, it is essential to ensure that the NPSHr of the pump is met. The NPSHr value is provided by the manufacturer and indicates the minimum pressure required at the suction port to avoid cavitation. This value varies based on the pump model and operating conditions.

Elastomer Properties and Limitations

Get Social